Introduction:

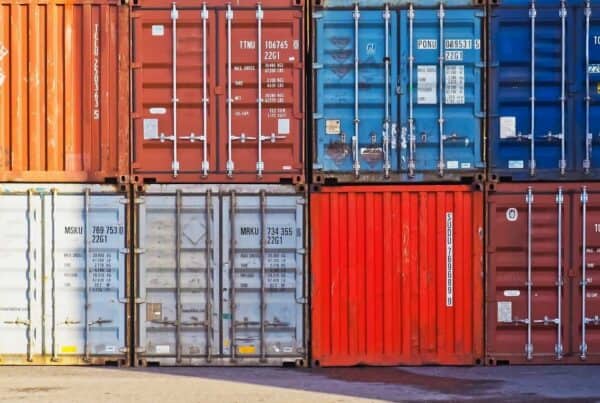

Shipping containers play a crucial role in global trade, ensuring the efficient and safe transportation of goods across long distances. When it comes to shipping general cargo, selecting the right type of container is essential. Various container options are available, each with its own features and suitability for specific types of cargo. In this article, we will explore the different types of shipping containers best suited for general cargo, considering factors such as size, construction, and compatibility.

Dry Van Containers: Dry van containers are the most common and versatile type of shipping containers. They are enclosed and weatherproof, making them ideal for transporting general cargo that does not require temperature control. These containers come in standard sizes, such as 20-foot and 40-foot lengths, and offer secure storage and protection for a wide range of goods. Dry van containers are highly adaptable and can accommodate goods like machinery, equipment, consumer goods, textiles, and packaged products.

Open-Top Containers: For cargo that exceeds the height limitations of a standard dry van container, open-top containers are the preferred choice. They feature a removable tarpaulin or hardtop roof, allowing for easy loading and unloading of oversized cargo through the top. Open-top containers are commonly used for goods like machinery, industrial equipment, construction materials, and goods that require crane access during loading and unloading.

Flat Rack Containers: Flat rack containers are suitable for cargo that cannot be loaded through the standard container doors due to size or shape constraints. These containers have collapsible or fixed ends, providing an open space for loading goods from the sides. Flat rack containers are commonly used for transporting heavy machinery, vehicles, pipes, construction materials, and oversized cargo like boats or yachts.

Reefer Containers: Reefer containers, or refrigerated containers, are designed for cargo that requires temperature-controlled transportation, such as perishable goods or pharmaceuticals. These containers maintain a specific temperature range, ensuring the preservation and freshness of the cargo. Reefer containers are equipped with refrigeration units and insulation to regulate temperature and humidity levels. They are commonly used for transporting fruits, vegetables, seafood, dairy products, and pharmaceuticals.

High Cube Containers: High cube containers are similar to standard dry van containers but offer additional height. With an extra foot of interior height compared to standard containers, high cube containers provide more vertical space for cargo. This type of container is beneficial for goods that are voluminous but not particularly heavy. High cube containers are commonly used for light and bulky cargo such as furniture, textiles, plastics, and lightweight machinery.

Tank Containers: Tank containers are designed for transporting liquid or gas cargo. They are equipped with specialized tanks that can hold a variety of substances, including chemicals, fuels, and food-grade liquids. These containers ensure the safe containment and transportation of hazardous or non-hazardous liquids, offering features such as pressure relief valves and protective linings. Tank containers are widely used in industries such as chemical manufacturing, petroleum, and food and beverage.

Ventilated Containers: Ventilated containers are specifically designed to transport goods that require airflow, such as fresh produce, flowers, or other perishable items that need ventilation to prevent spoilage. These containers feature strategically placed openings or vents that allow for proper air circulation. Ventilated containers help maintain the quality and freshness of the cargo throughout the shipping process.

Insulated Containers: Insulated containers are designed to regulate temperature and protect cargo from extreme temperature variations. They provide thermal insulation, preventing heat transfer and maintaining a stable internal environment. Insulated containers are commonly used for transporting goods that require temperature control but do not necessarily need refrigeration. Examples include electronics, pharmaceuticals, and certain food items.

Platform Containers: Platform containers, also known as flatbed containers, are essentially flat platforms without sidewalls or roofs. They are primarily used for oversize or bulky cargo that cannot fit inside standard containers. Platform containers provide a solid and stable base for loading and securing heavy machinery, vehicles, construction materials, or any cargo that requires open space or special loading equipment.

Specialized Containers: In addition to the aforementioned container types, there are various specialized containers available to meet specific cargo requirements. These include hanging garment containers for clothing, car carriers for automotive transportation, and open-side containers for cargo that needs easy access from the side. Specialized containers are tailored to accommodate unique cargo needs, ensuring optimal safety and efficiency during transit.

Conclusion: Choosing the appropriate shipping container for general cargo is vital for ensuring the smooth and secure transportation of goods. The wide range of container options available caters to different cargo types, sizes, and transportation requirements. Dry van containers serve as the go-to choice for most general cargo, while specialized containers like reefers, flat racks, and open-tops address specific needs. Understanding the characteristics and advantages of each container type enables shippers to make informed decisions and optimize their logistics operations, ultimately contributing to successful and efficient global trade.